Copyright © Shenzhen Disperse Equipment Co., Ltd. All Rights Reserved. Site Map

- +86-13824381687

- 821742327@qq.com

- Room 302, Building D, Tangqian Zhongzhi Creative Park, Zhangge Community, Fucheng Street, Longhua District, Shenzhen City

As a key part of the lithium battery manufacturing process, the welding process is used to connect the aluminum/copper positive and negative current collectors, pole pieces, and battery packaging of lithium batteries. Any defects in the welding joints will significantly affect the performance of the lithium battery. consistency. Therefore, it is necessary to understand the ultrasonic welding process.

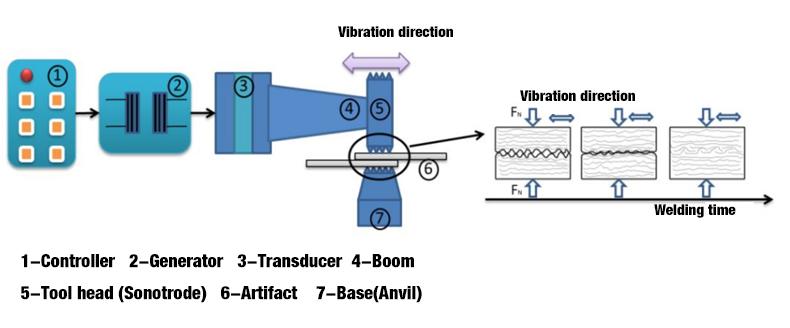

1. Principle of ultrasonic welding

During the ultrasonic welding process, the transducer converts high-frequency electrical signals into ultrasonic vibration signals. The high-frequency vibrations are transmitted to the surface of the metal to be welded through the welding tool head. Under the action of a certain pressure and severe friction of the ultrasonic vibration, the interface metal oxide film Broken, the interface is clean and the metal contacts, and under the combined action of friction and ultrasonic softening, plastic flow and diffusion are further generated, so that the connection area gradually increases, and finally a reliable connection is formed.

The formation of welded joints goes through two stages: the transition stage and the stable stage.

The transition stage is a short process of removing the surface film and oxides of the weldment, and the stable stage is the process of interdiffusion at the interface and stabilizing mutual diffusion. In the transition stage, the oxide film on the surface of the weldment is broken due to strong friction. At this time, friction is the main heat source. The increase in the temperature of the workpiece reduces the yield strength of the workpiece material, which is conducive to the breakage and plastic deformation of the oxide film on the surface of the workpiece, and the formation of joints. important role.

In the stable stage, the friction effect weakens after the metal contact surface becomes smooth, and heat accumulates at the welding interface due to plastic deformation. The heat in this process is generated by the plastic deformation process of the workpiece. The pressure exerted by the tool head causes the interface atoms to The metal joining process formed by generating force.

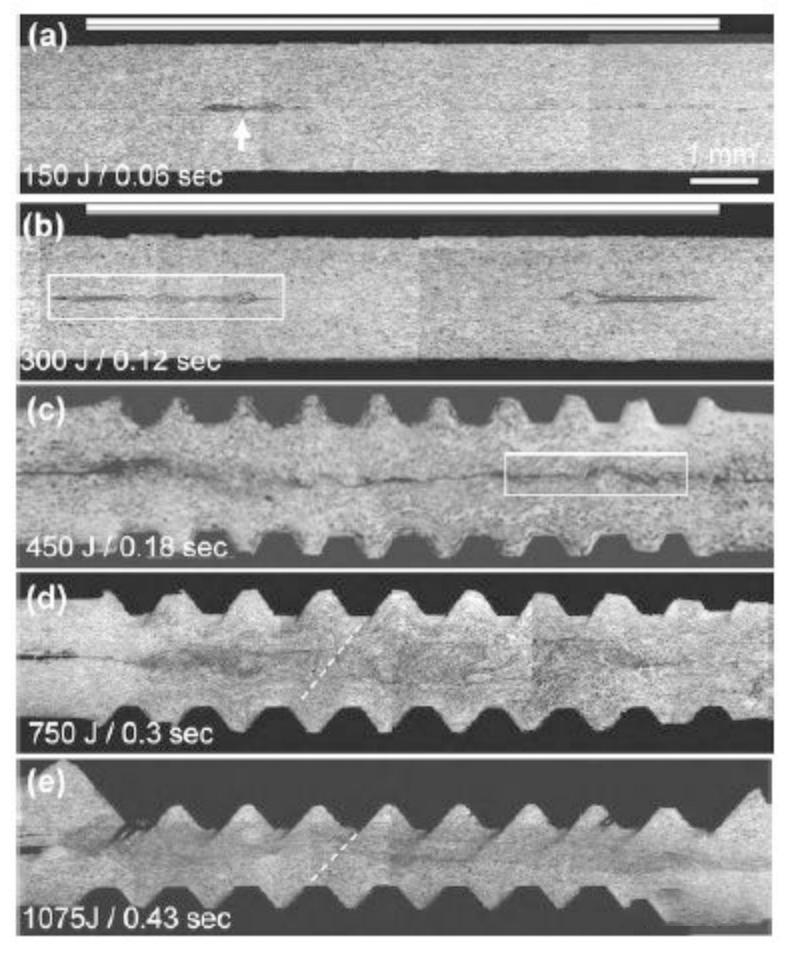

The plastically deformed workpiece in the welding area and the workpiece connection interface only have connections under the indentation grooves. The sum of the connection lengths under all grooves in the joint connection interface gives the sum of the joint connection lengths, which is called the effective connection length and is also an amount of plastic deformation Metrics.

2. Research on ultrasonic metal welding process parameters

The main process parameters of the ultrasonic metal welding process include welding pressure, welding energy/time, tool head amplitude and tool, head tooth pattern and size, etc.

(1) Effect of pressure

Welding pressure has a significant impact on the quality of welded joints. The strength of welded joints first increases and then decreases with the increase of pressure. The welding pressure will change the sliding resistance of the welding interface. A low welding pressure will result in a small sliding resistance of the interface, so that the energy generated by friction is not enough to form an effective connection at the interface. Excessive welding pressure will cause the tool head to be pressed too deep and the welding interface will be damaged. The metals bite each other, which affects the relative movement of the interface, hinders further connection of the interface metals, and causes the mechanical properties of the welded joint to deteriorate. Therefore, appropriate welding pressure parameters are decisive for welding quality.

(2) Influence of time

The welding time directly affects the energy input during the welding process and has a direct impact on the welding effect. The welding time is too short and the input energy is insufficient. Due to insufficient friction, it is difficult to form an effective solder joint. As the welding time increases, mutual friction causes the temperature to rise, the workpiece material begins to soften, and the interface oxide film in the welding area is damaged and plastic deformed. , can form a better connection; when the welding time is further extended, the welding head is easy to form deeper marks on the surface of the workpiece, which has an adverse impact on the welding effect. In addition, too long welding time can easily cause the welding head to be separated from the workpiece to be welded. bonding;

(3) Influence of amplitude

The amplitude of the vibration system formed between workpieces during the ultrasonic welding process directly affects the instantaneous speed of vibration at the workpiece interface, ultimately affecting frictional heating and plastic deformation, affecting welding quality.

(4) Influence of welding head

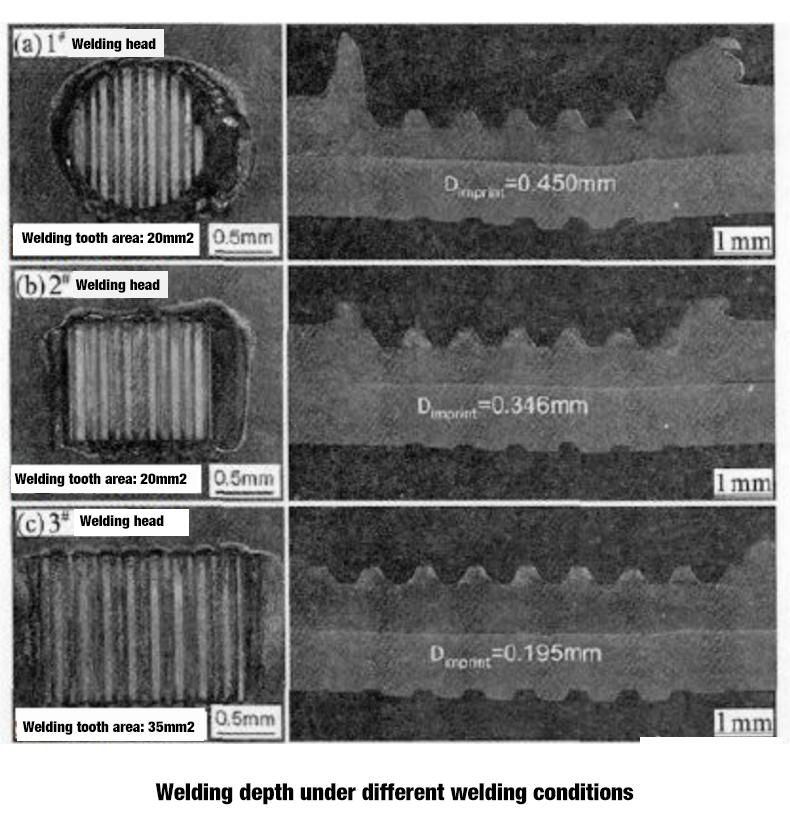

The welding head is a key component of ultrasonic metal welding. During the welding process, the welding head must grasp the workpiece to be welded under pressure. In this way, the mechanical vibration generated by the ultrasonic welding machine can be transmitted to the interface of the workpiece to be welded to form a solid-phase connection. Different areas of the welding head will lead to different distribution of welding pressure during the welding process, that is, the connection interface has different stresses, resulting in different friction during the welding process, resulting in different frictional heat generation during the welding process, resulting in different workpiece temperatures during the welding process. , ultimately affecting the quality of the joint. The depth of the welding head pattern determines the difficulty of embedding the welding head pattern into the surface of the workpiece. It also directly affects the depth of indentation on the surface of the workpiece, indirectly affects the temperature of the workpiece during the welding process, and affects the quality of the joint. Therefore, the shape and size of the welding head play a very critical role in the quality of the joint.

When the welding head area is the same, the plastic deformation of the rectangular welding head is stronger than that of the circular welding head; when the welding head shape is the same, the welding head with a larger area can cause the plastic deformation of the welding area to be stronger.

When the welding head area is the same, the round welding head is more likely to extrude the workpiece material under the welding head, forming a deeper indentation; when the welding head shape is the same, the small area welding head makes the pressure in the contact area of the workpiece surface larger, thus forming Deeper indentation.

3. Welding quality monitoring

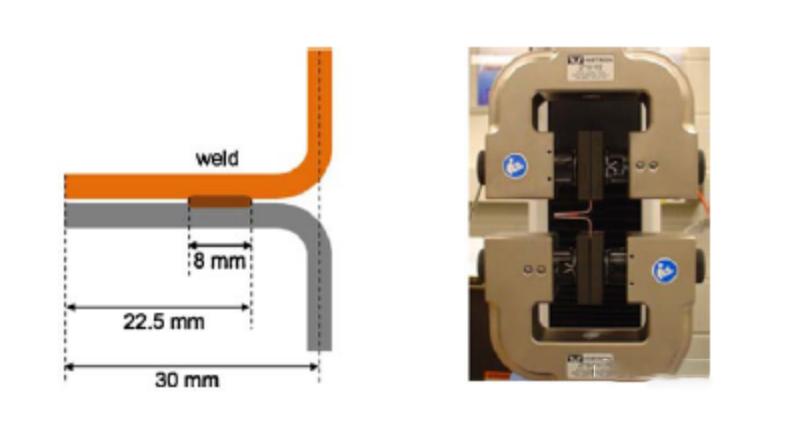

(1) Destructive testing

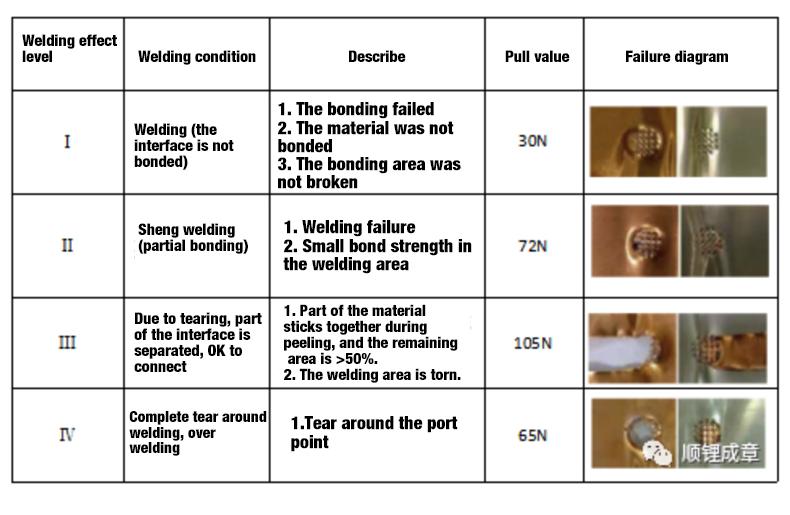

The quality of ultrasonic welding can be directly judged by testing the tensile strength of the welding area. When there is insufficient welding or over-welding, the tensile strength value will be very low.

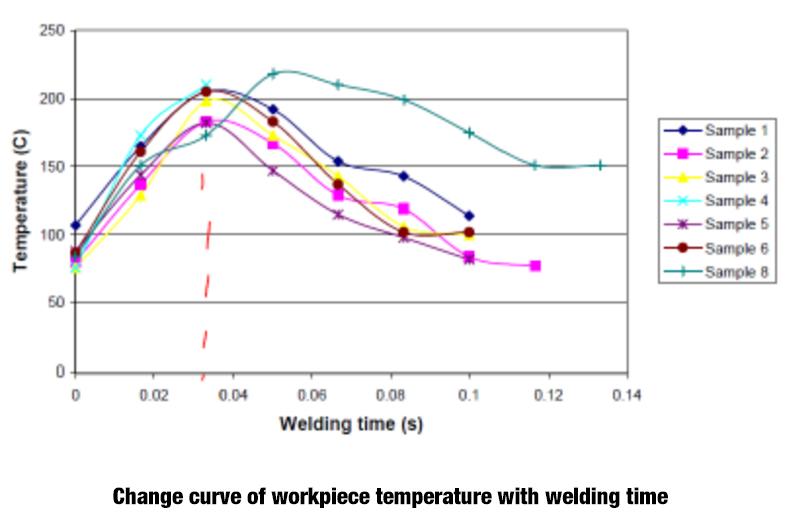

(2) Infrared test

Different welding process parameters will lead to changes in the total welding energy supplied by the welding machine to the workpiece to be welded, which will inevitably cause different friction effects during the welding process, resulting in changes in the heat generated during the welding process, and the temperature of the workpiece during the welding process will also change accordingly. The temperature of the welding head-workpiece contact area can effectively reflect the joint strength, and the joint quality can be predicted by measuring the temperature of the workpiece during the welding process. However, the higher the temperature of the contact area, the better. For each type of material to be welded, there is a critical temperature value. When the workpiece temperature is less than the critical temperature, the higher the temperature, the higher the strength of the joint; when the workpiece temperature is greater than the critical temperature, the joint strength will be higher. The intensity will weaken.

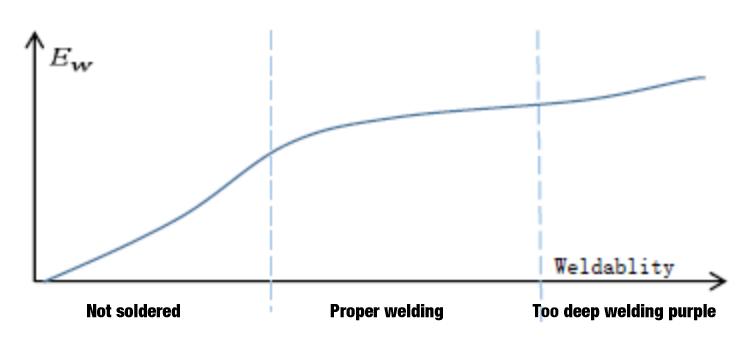

(3) Energy feedback

Different welding parameters and different welding effects require different energy, which can be judged by detecting the welding energy during the welding process.